Thermoplastic Kiln Sticks for Lumber Drying

Upgrade to Thermoplastic Kiln Sticks for Superior Performance

For years, wooden kiln sticks have been the standard in industrial drying processes, but they present significant limitations. They are prone to warping, cracking, and staining, resulting in frequent replacements and disruptions in production. Preferred Plastics offers a superior alternative: thermoplastic kiln sticks engineered for exceptional durability, stability, and efficiency.

Need a custom solution? We provide cut-to-order options to ensure your kiln sticks integrate seamlessly into your operations.

The Drawbacks of Wooden Kiln Sticks

While wood might seem like a cost-effective option, it comes with several hidden drawbacks:

- Susceptibility to Heat Damage and Warping: Wooden sticks tend to lose their shape under heat, leading to unstable stacks and uneven drying processes.

- Short Lifespan and Frequent Replacements: The need for constant replacement increases both material and labor costs.

- Fire Risk: Wood is inherently flammable, whereas our thermoplastic sticks carry a B1 fire rating and are self-extinguishing, significantly reducing fire hazards.

- Inconsistent Dimensions: Variability in wood dimensions can cause stacking problems, affecting airflow and drying efficiency.

Precision is crucial when drying lumber, ceramics, or other materials. An inefficient kiln setup can lead to increased downtime, waste, and operational costs.

Why Thermoplastic Kiln Sticks Outperform Wood

Preferred Plastics’ polycarbonate kiln sticks are designed to excel in demanding environments, offering several advantages over traditional wooden sticks:

- High-Temperature Resistance: Capable of withstanding temperatures up to 220°F without warping, splitting, or weakening.

- Extended Service Life: These kiln sticks require fewer replacements, resulting in lower long-term costs.

- Consistent and Stable Dimensions: Precision-cut for perfect stacking and enhanced airflow, ensuring efficient drying.

- Eco-Friendly Choice: The durability and recyclability of thermoplastics reduce material waste over time.

- Customizable Options: Available in multiple cross-sections and customizable lengths to meet specific operational needs.

Engineered for Industrial Excellence

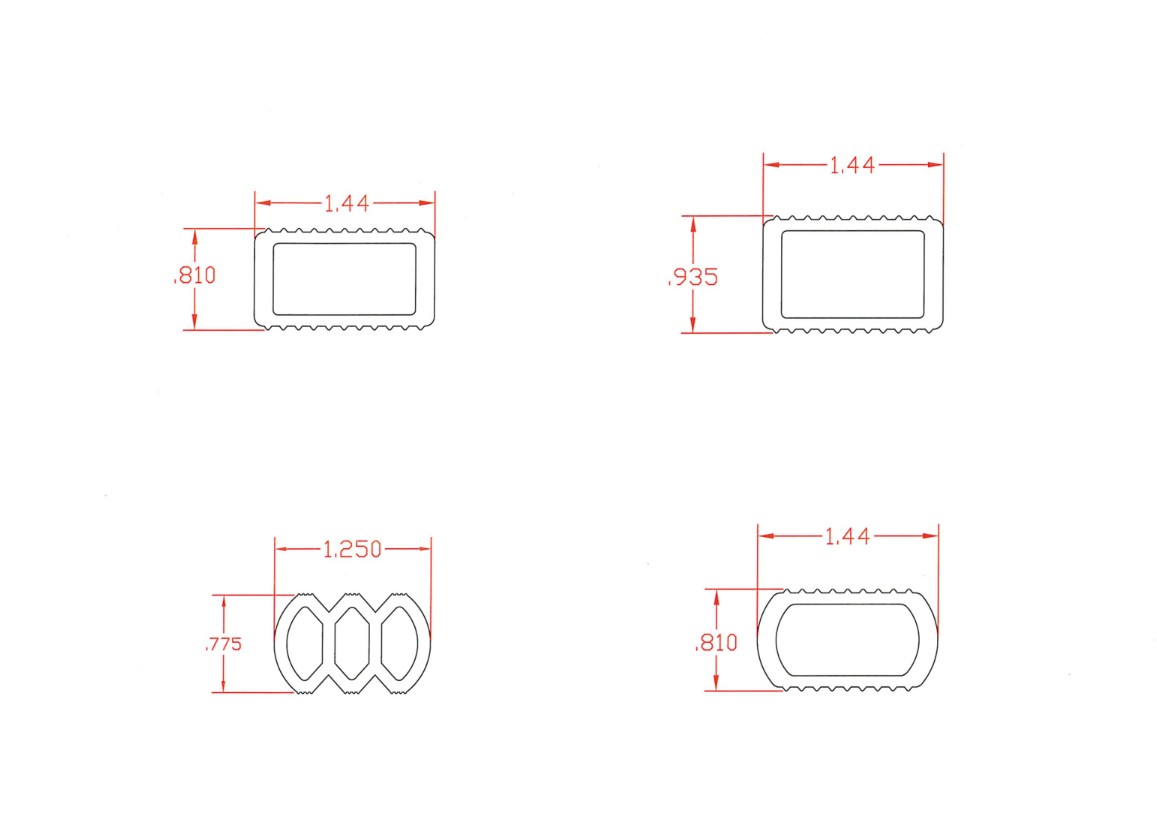

Our kiln stacking sticks are available in various configurations to suit both automated and manual kiln processes.

Available Sizes:

- .775” x 1.250” Triple Hollow Curved Edge

- .810” x 1.440” Flat Edge

- .935” x 1.440” Flat Edge

- .810” x 1.440” Curved Edge

Need a specific solution? We offer cut-to-order options to ensure seamless integration into your operations.

Boost Efficiency, Reduce Waste, and Save Costs

Choosing thermoplastic kiln sticks isn't just a performance upgrade; it’s a strategic move for long-term cost savings.

- Durability: Lasts significantly longer than wood, minimizing the need for frequent replacements.

- Reduced Maintenance Costs: With no warping, production delays are minimized.

- Sustainable Solution: A durable, recyclable material that decreases landfill waste.

Every unnecessary material swap costs money. Thermoplastic kiln sticks eliminate inefficiencies, offering significant savings.

Trusted by Industry Experts

With over 40 years in high-performance thermoplastic extrusion, Preferred Plastics is the industry's trusted choice for reliable solutions.

- ISO 9001:2015-Certified Manufacturing: Ensures consistent quality and performance.

- Custom-Engineered Solutions: Tailored to meet specific industrial needs.

- Proven Industrial Performance: Dependable results in challenging drying environments.

- Proudly Made in the USA: Manufactured in Southwest Michigan.

When efficiency and reliability matter, our thermoplastic kiln sticks deliver superior results that traditional wood cannot match.

Get Your Custom Quote Today

Stop relying on cracked, warped wooden kiln sticks that hinder production. Upgrade to thermoplastic kiln sticks for a stronger, more reliable drying process. Contact Preferred Plastics today for pricing, customization options, and expert recommendations tailored to your specific needs.